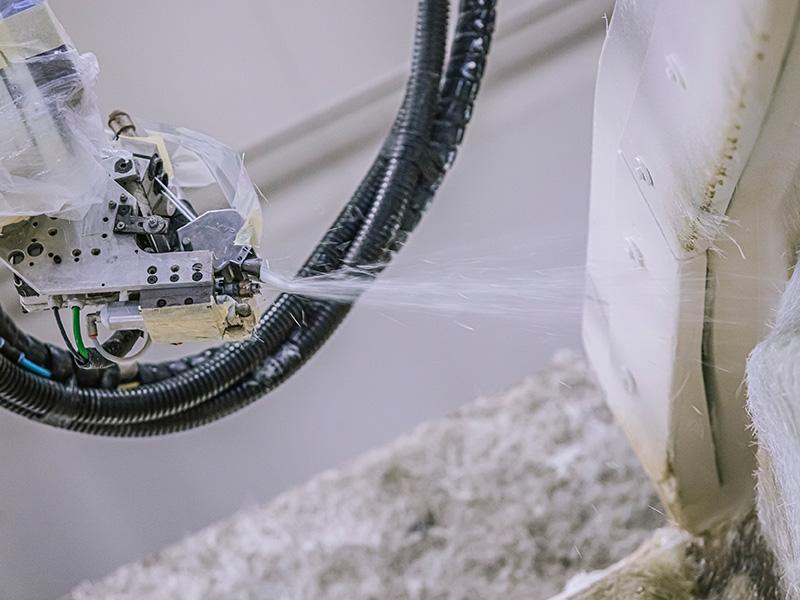

Cranchi Yacht- Kawasaki robot for resin spraying operations

GOAL

To maintain and guarantee over time the high quality levels achieved over the years.

ROBOT

FS010L robot

FS020X robot

DETAIL

Two robot islands

Cranchi Yacht is an Italian company that has been spreading technological excellence, design and beauty around the world in the pleasure motor boat sector for over 150 years.

At its Piantedo Plant 1 and Seventy Plant 4 production facilities, avant-garde technological poles located in the towns of Piantedo and Rogolo, respectively, in the province of Sondrio in Lombardy, Cranchi builds the iconic yachts that are universally recognised as the industry benchmark.

Cranchi Yacht has entrusted Tiesse Robot with the automation of its plants, achieved with the installation of two robotic islands aimed at maintaining and guaranteeing over time the standards of excellence in the fibreglass and top coat spraying process achieved over the years.

The Piantedo Plant 1 - which is also Headquarters, Research Centre, Purchasing Centre and Spare Parts Centre - is dedicated to the production of boats from 26 feet up to 46 feet (A46 Luxury Tender) on a total area of 70,000 m2.

The island installed at Piantedo Plant 1 consists of a robotic system with a Kawasaki FS010L robot that sprays fibreglass (consisting of resin, catalyst and 2 rowing wires) on boat components up to a maximum size of 12 x 4.2 x 2.8 metres.

The plant consists of an overhead gantry with freedom of movement along XYZ axes, which allows the robot to move within the working area of the plant.

Seventy Plant 4 is dedicated to the production of boats up to 80 feet and covers a total area of 140,000 m2.

Seventy Plant 4 is served by an island equipped with Kawasaki FS020X robots, which handles the cutting and spraying of fibreglass and top coat on larger boat components up to a maximum size of 24 x 7.1 x 7.1 metres. The plant consists of an overhead gantry with freedom of movement along XYZ axes, which allows the robot to move within the working area of the plant.

Cranchi Yacht's skilled technicians work every day alongside Kawasaki industrial robots in total safety, collaborating in a rigorous process where each phase is planned and verified in detail; this is made possible thanks to the installation of a volumetric detection system around the robot's work area that monitors any interference with the operator.

Both islands are equipped with two side-by-side workstations that are serviced by the same robot. They also have a part type recognition system using a TAG reader that selects the robot programme; subsequently, with a part position recognition sensor, the robot automatically recalibrates the programme.

Take the first step and contact us!