Insights into the world of industrial robotics

The BXP210L is the new jewel in the series of robots developed by Kawasaki Robotics for handling large weights.

No compromise: maximum performance and efficiency

We already anticipated this a few months ago, and just in the last few weeks Kawasaki Robotics presented 'Green Robotics, for a sustainable future'.

CL Series collaborative robots

In today's era of rapid technological innovation, robotics plays a central role in the evolution of industry.

A robot lab in the kitchen of PizzaCroccante

Automation has been an integral part of industry for many years: from robotic welding islands to cutting and deburring systems, from anthropomorphic handling arms to assembly plants. However, in the kitchen, Kawasaki Robotics robots have never been seen... or almost!

In the increasingly innovative landscape of collaborative robotics, the Kawasaki Robotics CL Series stands out: a range of four models that combine safety, flexibility and a small footprint.

Record number of robots sold and a prestigious award

Tiesse Robot is pleased to announce the extraordinary result highlighted and awarded at the Kawasaki Robotics Global Meeting, which brought together Kawasaki robot distributors from all over the world.

A completely new and agile approach to collaborative robotics

Kawasaki Robotics introduces the new CL Series line of collaborative robots.

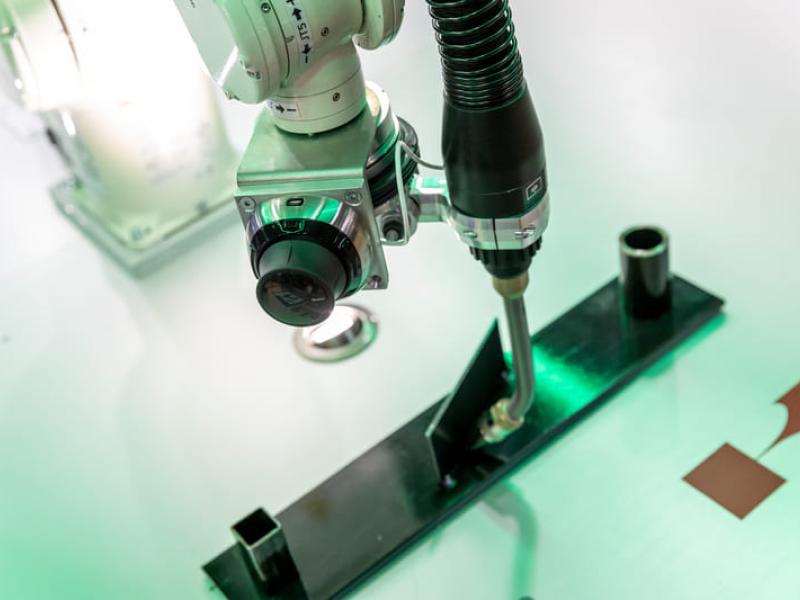

Intuitive and simplified, allows quick robot teaching

Dario Daprà, Sales Engineer at Tiesse Robot, presents the features and details of K-DIY.

Literally "Kawasaki do it yourself".

One complete and modular cell, suitable for MIG and MAG welding

Dario Daprà, Sales Engineer at Tiesse Robot, shows us the details and features of K-ARC: the complete turnkey solution from Kawasaki Robotics dedicated to arc welding.

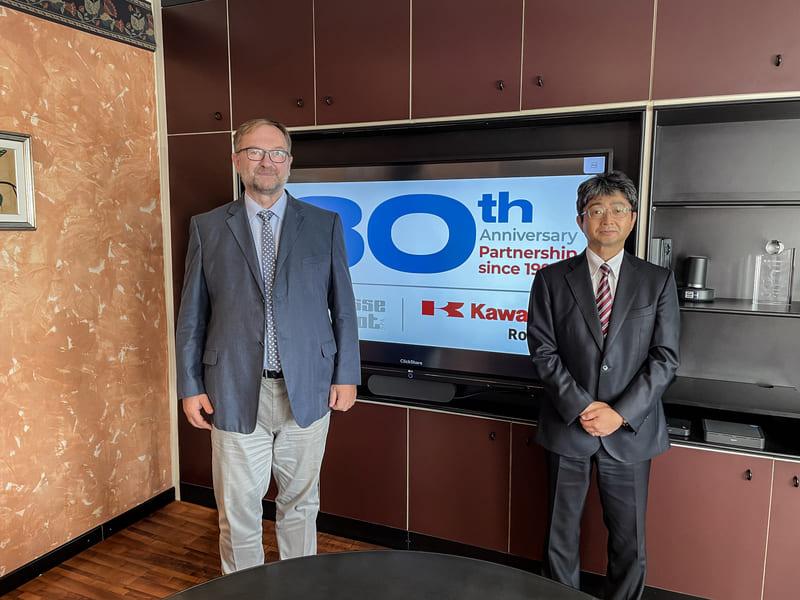

A success story around the world and a union born of a common drive towards the frontiers of technology and innovation.

Telling 30 years of history can be difficult because one has to retrace with the memory numerous achievements of a partnership that, with determination and ambition, has grown continuously: that between the Japanese giant Kawasaki Robotics and the Italian Tiesse Robot.

A whole new approach to learning, and teaching, industrial robotics

The world of work and the way we work is changing rapidly, and educational institutions - technical colleges and universities - need to be ready, and prepared, to train future robotics engineers.

All K series models are explosion-proof and ATEX category G2 T4 certified

Dario Daprà, Sales Engineer at Tiesse Robot, presents the features and technical details of the KJ125 robot: versatile and lightweight, it is perfect for all industrial and automotive painting applications.