Robotized systems for arc welding operations

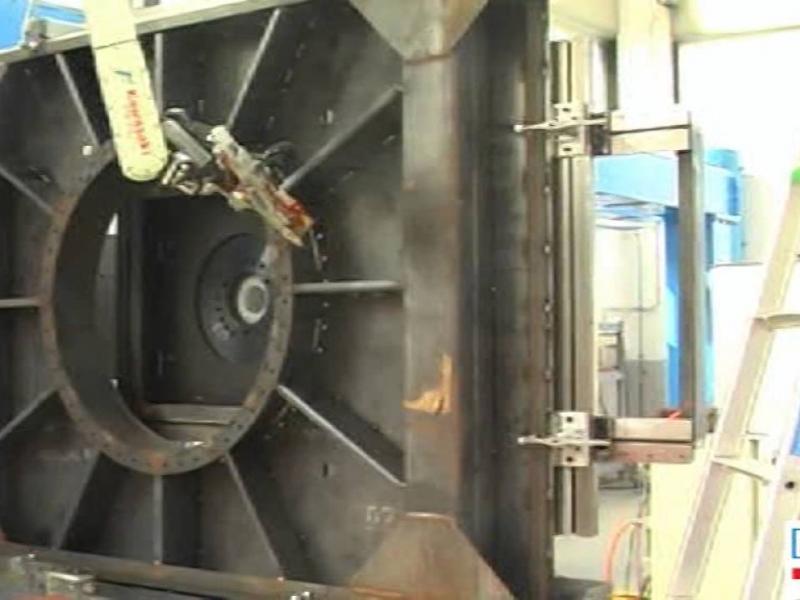

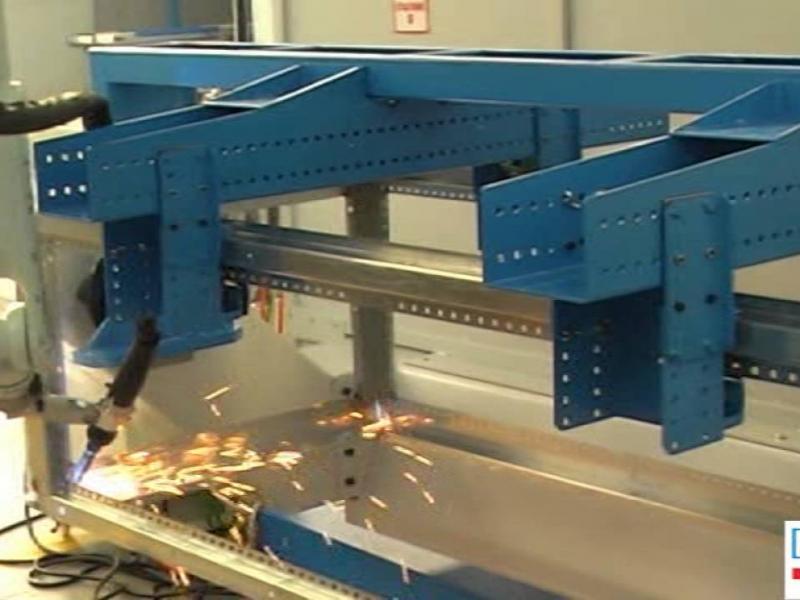

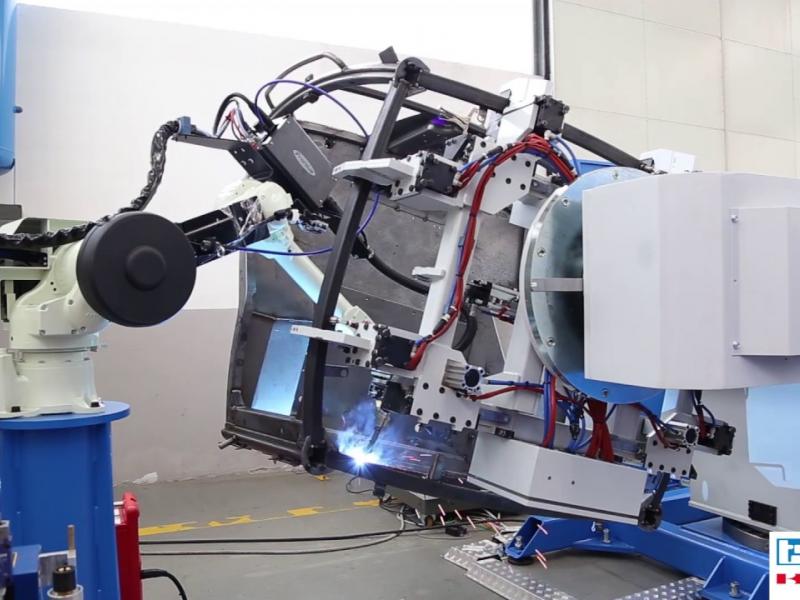

Arc welding is the historical sector to which Tiesse Robot has always offered technological and performing solutions by designing and manufacturing precise and versatile robotic systems with the help of robots with load capacities up to 20 kg and arm extensions up to 2.36 meters.

In this area has proved particularly effective and valid the contribution of Kawasaki robots for features such as machine speed, precision of trajectories, flexibility of software packages and programming through off-line systems.

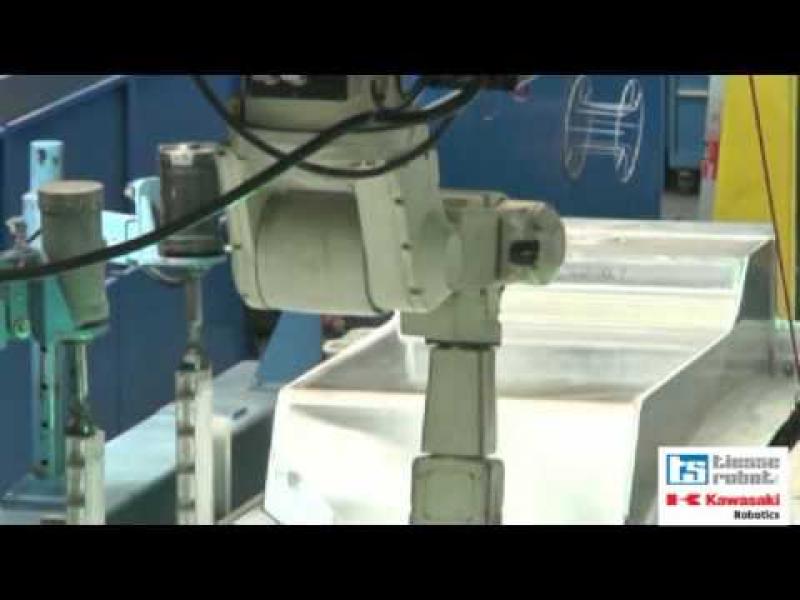

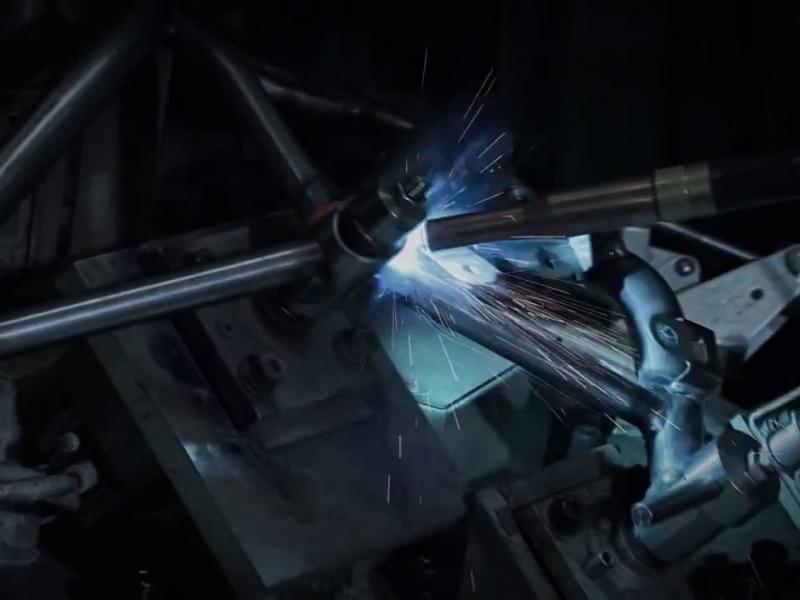

The robotic systems for arc welding operations perform Mig, Mag single and double wire, Tig welding and are equipped with joint tracking sensors, traditional or with cameras and laser scanners.

Tiesse Robot, thanks to the highly advanced communication protocols of Kawasaki robots, holds a leading position in this sector and has refined its technological resources and process knowledge to the point of creating complete robotic islands, based on modular construction and used in the agricultural, automotive, transport and furniture sectors.

DOWNLOAD

Download the available material here.

HISTORY

Euromecc - robotized welding with Kawasaki robots

Leader in the design and production of machines and plants for the concrete and cement industry, has entrusted Tiesse Robot with the automation of its factory with the installation of three robotic welding systems.

Read more

METRA- Kawasaki robot for welding operations

It has entrusted Tiesse Robot with the automation of its welding process of aluminium components for the railway sector, with the aim of increasing the precision and speed of highly repeatable welding operations.

Media Gallery

Watch the robotic systems for arc welding operations at work

Take the first step and contact us!

Zooming in on the world of industrial robotics

Interviews, news and insights concerning robots and industrial automation.