IMA Life- Kawasaki robots used in pharmaceutical insulators

GOAL

Avoid the risks of contamination, errors and non-compliance with operating procedures associated with operator intervention.

ROBOT

Robot Kawasaki MC004-V

DETAIL

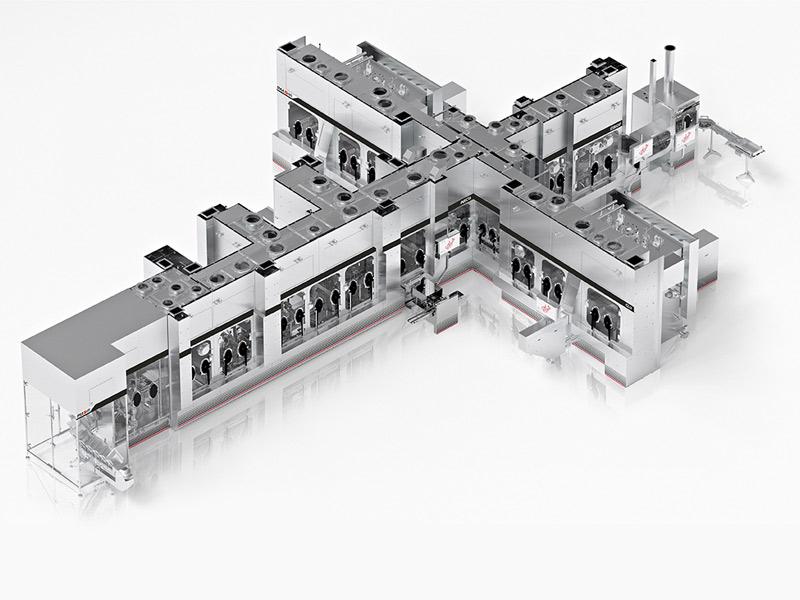

Injecta

IMA Spa Life Division, based in Ozzano dell'Emilia in the province of Bologna, is a world leader in the design and manufacture of automatic machines for the processing and packaging of pharmaceutical products.

The automatic machines developed and manufactured by IMA Spa Life Division can be perfectly integrated into complete processing lines, handling the decontamination of containers, the aseptic filling of cartridges, vials, syringes and other containers with pharmaceutical liquids and powders.

Together with Tiesse Robot, supplier of Kawasaki robots, IMA Spa Life Division has set a new standard in aseptic processing, responding to the demands for greater flexibility, speed, precision and process quality dictated by the regulatory world of the medical sector for the production of injectables.

The INJECTA series takes full advantage of robotic automation applied to pharmaceutical isolators and the use of the Kawasaki MC004-V handling robot:

- allow the use of a single machine for different types of filling

- reduce change-over time

- minimise manual operations

The Kawasaki MC004V robot is equipped with 6 degrees of freedom, VPHP resistant coating, 4 kg payload, IP65 grade ensuring total protection against penetration by solids and liquids, hollow wrist with fully integrated cables and piping.

Fraunhofer Ipa is the institute that carried out the laboratory tests to validate the use of the Kawasaki MC004V robot for the automation of pharmaceutical isolators: from the hygienic design of the mechanics and external components to the ease of decontamination and cleaning.

The video shows the INJECTA series at work, which, with accuracy - precision - reliability, manages the filling with pharmaceutical liquid and the capping of vials.

Take the first step and contact us!