METRA- Kawasaki robot for laser cleaning operations

GOAL

To perfect the yield of the finished product.

ROBOT

RA020N

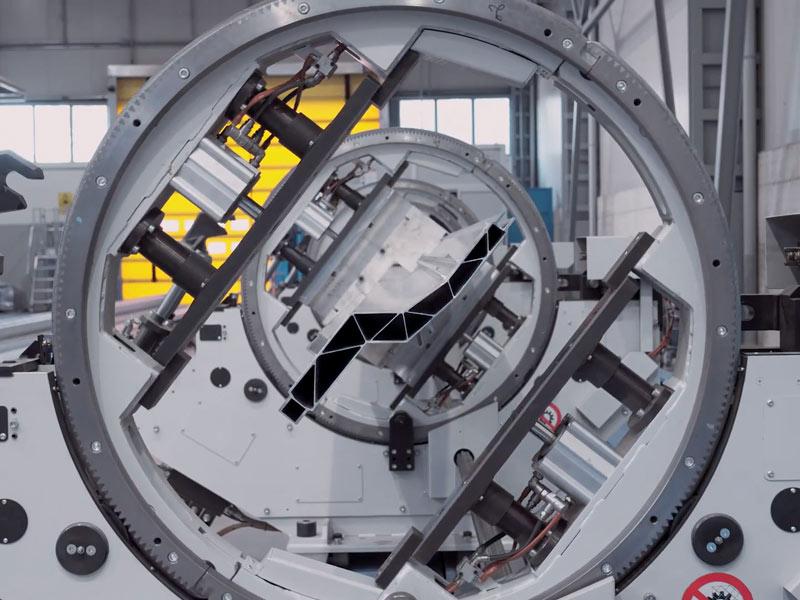

DETAIL

Special clamping equipment that allows the correct clamping and rotation of the part in order to carry out complete machining with just one tool.

For 60 years, aluminium has been the main ally of METRA, a Brescia-based company capable of offering profound know-how to different markets and production chains: from the road and rail transport industry to mechanical and pneumatic production, from furniture and interior design to construction and architecture.

METRA's leading position is the result of decades of updating, experience and technological investments aimed, among other things, at automating the cleaning and finishing process of components.

The Rodengo Saiano plant is served by a robotic island for laser cleaning operations, designed and built by Tiesse Robot.

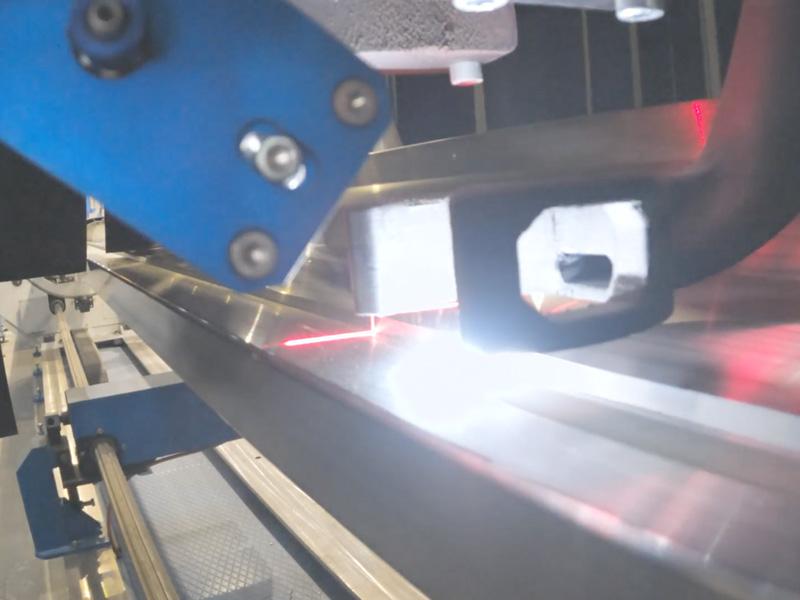

In detail, it features a Kawasaki RA020N robot equipped with a Fujikura Q-Switch 100 w laser source and its galvanometric XY digital process head, all optimised for the cleaning process.

The industrial robot is installed on an RT3000 rail with a useful travel of 25 metres; the laser protection cabin is also fixed to the carriage where the robot is installed, which moves accordingly on the rail together with the robot.

Servorobot's Power-Trac laser joint tracking sensor allows the adaptive process to recognise the profile of the part to be cleaned and ensures the correct machining position.

There is also a special fume extraction system.

The special clamping fixtures are specifically designed for the parts to be cleaned and allow them to be clamped and rotated correctly so that complete machining can be carried out with just one tool.

Take the first step and contact us!