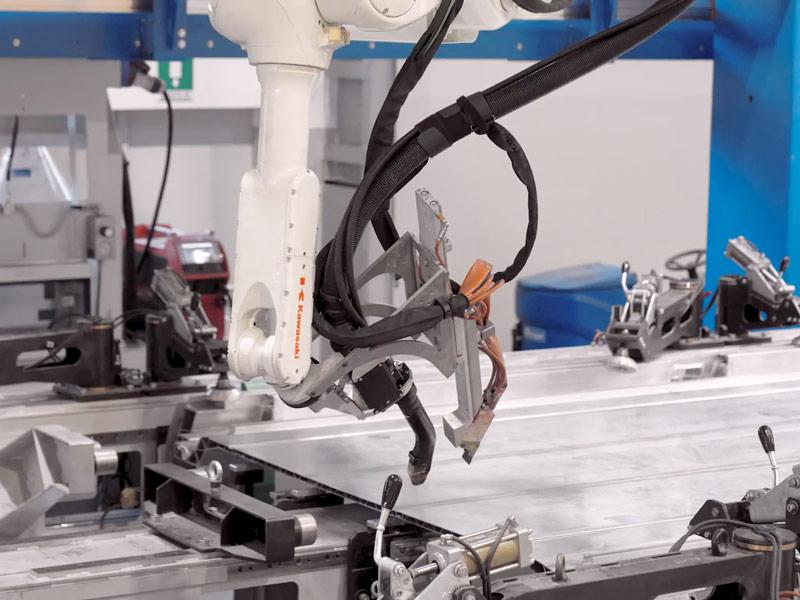

METRA- Kawasaki robot for welding operations

GOAL

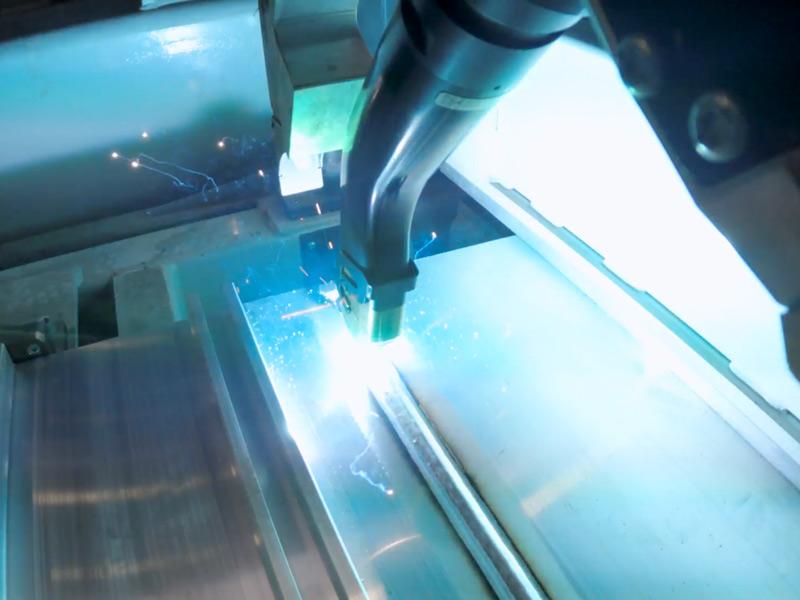

To increase precision and speed in welding operations.

ROBOT

Kawasaki robot RA020N

DETAIL

Positioners with a 20-metre plate span, a 20,000 kg capacity and a tilting function for rotating the equipment.

The METRA Group has been serving markets around the world in the aluminium extrusion industry with custom-made solutions for over 60 years. The Group's great strength, besides its extreme knowledge of multiple production processes and geographical markets, is its integrated production cycle: from foundry to extrusion, from machining to welding, from finishing to logistics.

All under one roof, that of METRA's Rodengo Saiano site in the province of Brescia.

It has entrusted Tiesse Robot with the automation of its welding process of aluminium components for the railway sector, with the aim of increasing the precision and speed of highly repeatable welding operations. Welding takes place within a dedicated new-generation plant, covering a total area of 6,500 m2, equipped with gantries up to 30 metres long. The robot cell features an RA1 overhead monorail with X- and Y-interpolation and a 65-metre stroke on which two robot carriages with independent movement are installed.

Both robots are from Kawasaki Robotics, model RA020N, equipped with Fronius TPS600i Pulse Twin wire CMT pulsed arc generators complete with push-pull twin wire torch and related accessories.

Servorobot's Power-Trac laser joint-tracking sensor allows an adaptive process to recognise the profile of the part to be welded and ensures the correct welding position.

Both robots are equipped with a fume extraction hood and related purification systems.

The two workstations are equipped with positioners with a 20-metre plate span, a 20,000 kg capacity and a tilting function for rotating the equipment.

The special fixtures are modular and designed specifically for the parts to be welded, and are designed to clamp the various components in the correct position.

Take the first step and contact us!